We can do it. Really well.

Competencies. Core competencies.

Simple or complex CNC turned parts, or precision turned parts with small and large diameters of up to 300 mm – the modern machine park of our turning shop can do all this. Likewise, it also provides economic production of multi-spindle turned parts, plain turned parts, short turned parts, finely turned parts and chuck parts.

Always up-to-date: our machine park

Our turning and milling shop has state-of-the-art machinery such as CNC lathes, CNC machining centres, 5-axis milling centres and milling machines. Their manufacturers are the “Who’s Who” of the industry: Index, Buffoli, Nakamura, Deco, Gildemeister, Manurhin, Schaublin and Mikron. In addition, we have state-of-the-art grinding machines for surface grinding, plunge grinding, through-feed grinding, internal and external grinding, as well as cylindrical grinding and Trowal burring. We assemble the modules according to your custom specifications. Our service includes surface coatings and heat treatments by certified partners.

Your Robert Bischoff (Managing Director)

Convince and inspire with a wide range of qualities

“Of course, the core issue is the maximum quality of our CNC parts. However, combined with competent advice, efficient production processes and punctual delivery, our customers benefit from a comprehensive package with which we convince and inspire you anew for each project. It is no wonder that we have so many long-term customers. Let yourself be inspired too!”

Non-binding inquiry

CNC turned parts and milled parts at Harry Roth: everything from the finest

We at Harry Roth offer you the complete range of precision turned parts and milled parts. We have something for all your needs. The lot sizes range from small series right up to series production with more than 10 million units. Everything has in common the highest quality and precision, and cost-effectivenes:

Turning shop Harry Roth: We manufacture your turned parts and milled parts to measure

Are you looking for a turning shop that machines turned parts and milled parts economically and at the highest level of precision? Harry Roth is the answer. As a well-known company within the metal processing industry, we bring to the table many years of experience and the highest level of competence in the turning, milling and grinding of high-quality CNC parts. Our customers include global companies from within the automotive, mechanical engineering, drive technology, sensor technology, pneumatics, hydraulics, medical technology and aviation industries.

High-precision CNC turned parts with diameters ranging from 1 mm to 300 mm can be produced. We machine CNC milled parts up to a workpiece size of 1,000 x 800 mm. We can manufacture your products from all machinable materials, including titanium, aluminium, brass, steel, stainless steel and bronze. Special materials can also be processed.

We meet our 100% quality standards through the use of state-of-the-art machinery and high-performance measurement technology. We therefore guarantee perfect components according to your requirements.

For every need: Services and materials

If you want to have high-quality parts turned and milled from aluminium, brass, titanium, stainless steel, bronze or special materials, you’ve come to the right place! We have the experience, the machines and the expertise. With us, your requirements for metal contract manufacturing will be met one hundred percent. With 100% certified quality.

Well-known companies: we supply these industries with high-quality CNC parts

At Harry Roth, you will find the CNC parts you require for your application field – no matter whether this be automotive, mechanical engineering, drive technology, sensor technology, pneumatics, hydraulics, medical technology or aviation. You benefit from our know-how and the efficient production processes that we have optimized as a turning and milling shop over many years for a wide range of industries. We understand what you need; with us you always first receive extensive consultation. In the shortest possible time, you and your company will receive tailor-made parts of the highest quality from us.

Quality management

Our integrated management system provides the framework for consistent quality assurance measures – across all business processes. Already in the offer phase, we identify potential risks and reduce these by implementing appropriate preventive measures. We verify whether the necessary measuring equipment is available for production, or if it needs to be procured for the specific order. There are currently around 3000 calibrated measuring devices in our measuring equipment management system.

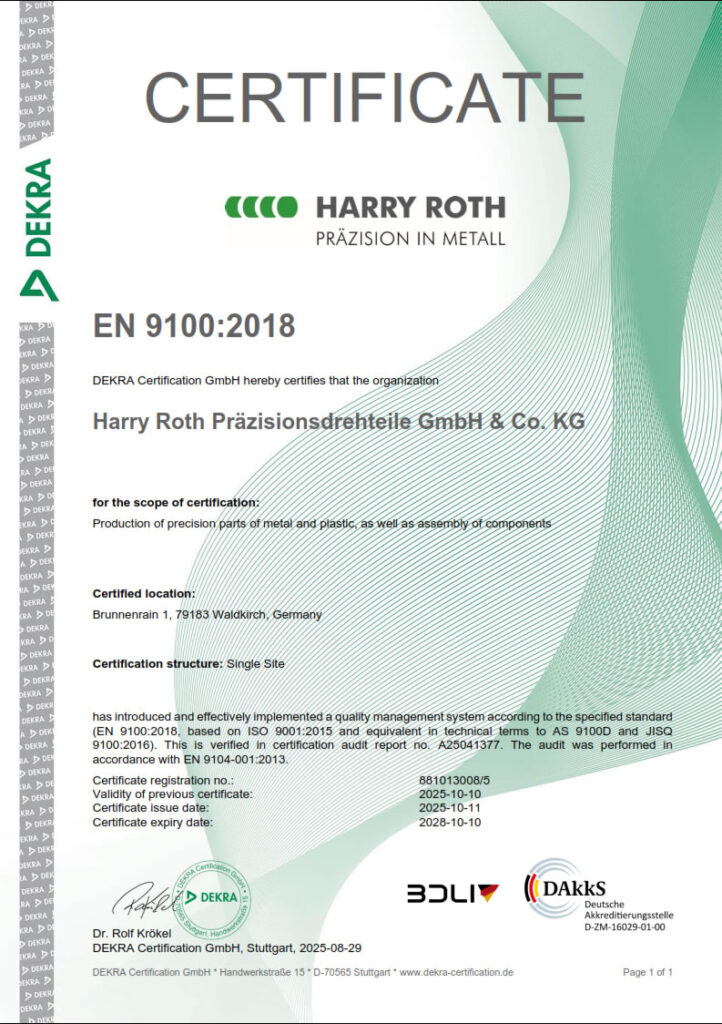

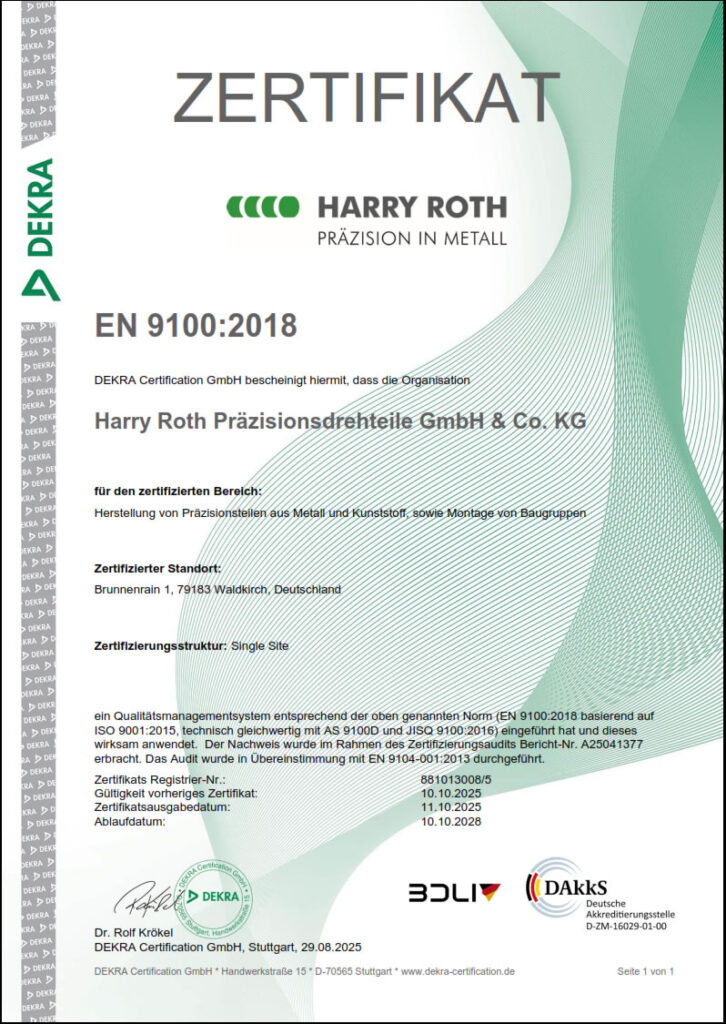

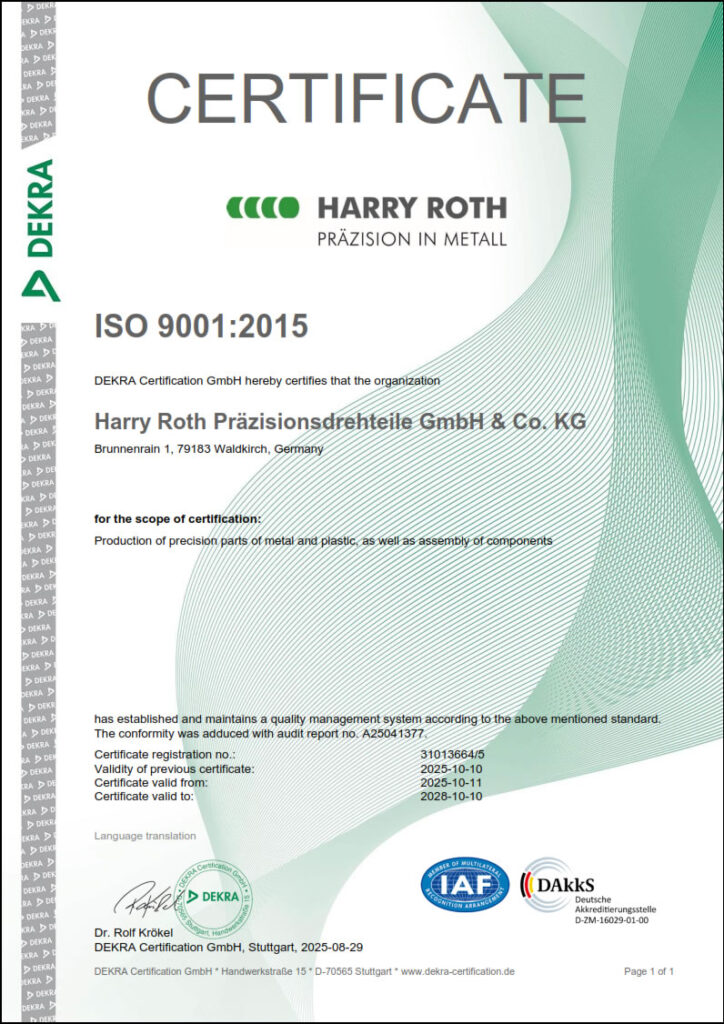

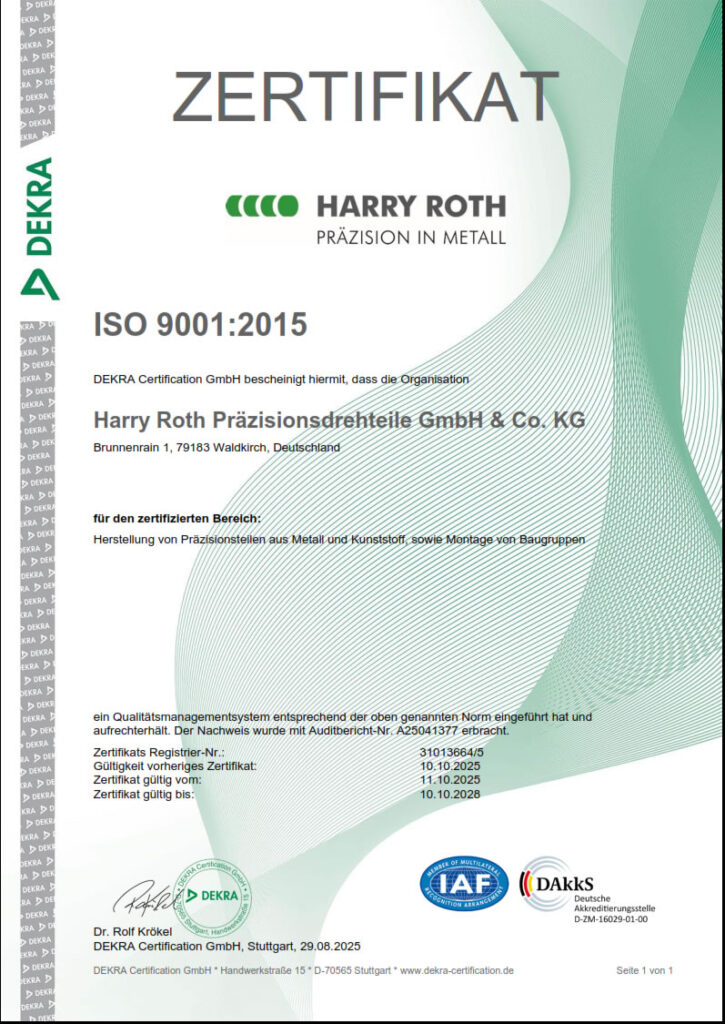

We are certified

DIN EN 9100:2018

English

German

ISO 9001:2015

English

German

Harry Roth

Präzisionsdrehteile

GMBH & CO. KG

Haben Sie eine

Frage? Rufen Sie an!

+49 (0) 7681 / 20080

Unsere E-Mail

info@harry-roth.de